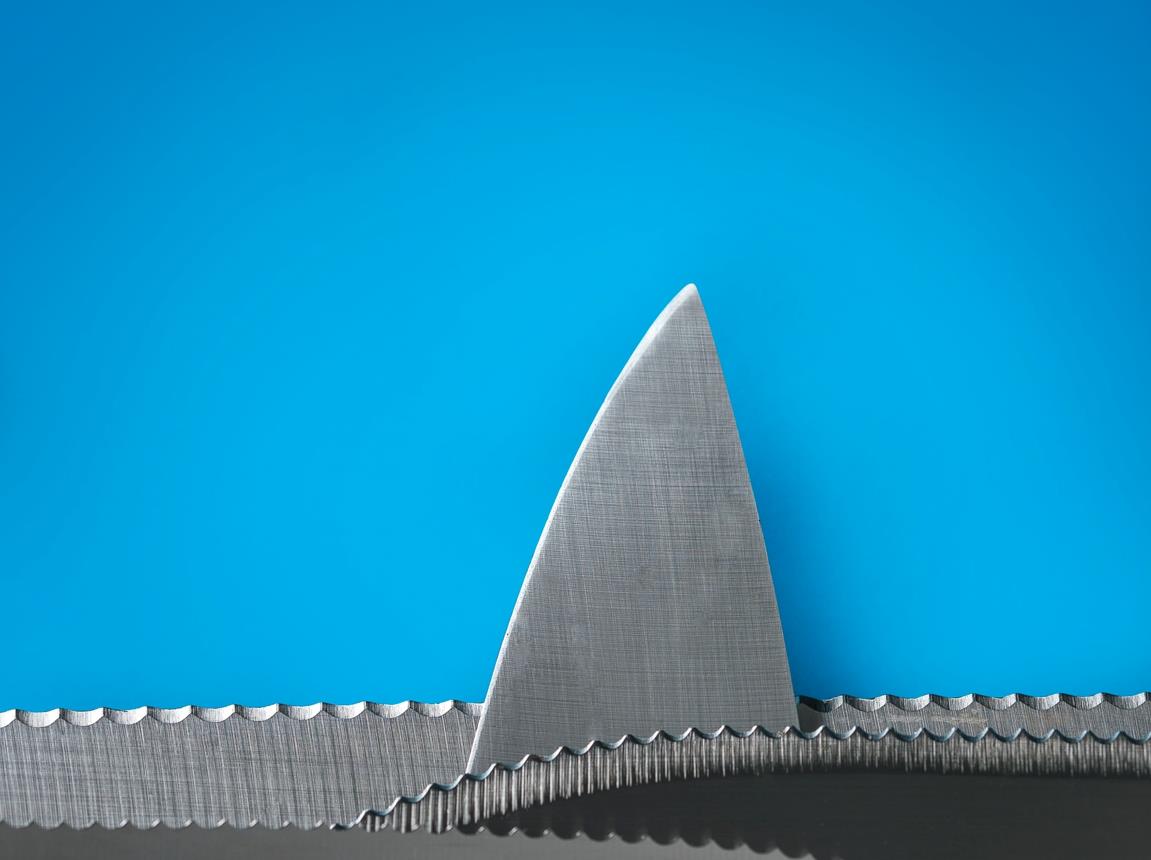

So, you decided your $10 chef’s knife won’t cut it anymore. I’ll let that joke sink in for a while.

What’s next? You could spend the better part of a day looking at different designs, materials and brands, but you know, deep down, that’s not going to help. You can’t just buy a knife someone recommends on the internet because internet strangers don’t know how you intend to use it.

The truth is, if you don’t know what to look for when buying a chef’s knife, you might end up with the latest fad that won’t help you much. I get it; the internet made me buy a lot of useless things. For you to get the most bang out of your buck, you will need to carefully consider your main priorities.

Then, you should look for the knife that will excel in the most important one or two aspects. Yes, that is indeed very vague. Don’t worry; I’ll teach you how to choose a chef’s knife that will become your ultimate sidekick, in the sections below. It’s actually easier than marketers will have you believe.

Table of contents

Identify your main priority

Going shopping without a certain set of particularities in mind will result in a lot of confusion and money misspent. I advise sitting down with a piece of paper and writing any cooking habits you have. Explore what ingredients you use the most, how much time do you spend cooking, and how much of that is knife handling.

Do you know how to keep your knives sharp? How often will you have the time to do that? Do you have a honing rod? How do you plan to clean your blade after using it?

What’s your storage situation like? Are you monumentally clumsy? Prone to cutting yourself or dropping the knife? What other types of knives do you already have?

This will take a lot of guessing work out of the process. For example, if you need a knife that will successfully handle all kitchen tasks, from peeling veggies to deboning meat, you might want to look for a sturdier knife. If you only sharpen your knives once a year (and be honest about it), you will want a blade that keeps its sharp edge for a longer time.

Japanese style chef’s knife vs Western-style knife

The gap between these two types of knives is slowly diminishing, but there are still a couple of things you should consider when choosing between them. Generally, a Japanese blade will be slim, razor-sharp, and pretty lightweight. They are amazing for precision work.

If you want to understand the difference between these knives, you should explore each culinary culture a little bit. Japanese cuisine uses a lot more vegetables, cut in particular ways. They are careful in the way they peel, chop and dice their veggies. They don’t use a lot of meat.

This makes their chef’s knives fantastic for vegetarians. For example, a Nakiri knife can be used for chopping vegetables of all kinds, from delicate tomatoes to hearty parsnips. But it also does a fantastic job at finely mincing cloves of garlic. In fact, its name comes from Nakiri bocho, which literally translates into “knife for cutting greens.”

Santoku knives are the equivalent of a Western chef’s knife, and their name translates to “three uses.” And these uses are mincing, dicing, and slicing. And they mainly refer to veggies. This knife is the modern version of the traditional Japanese vegetable knife.

In turn, Western knives follow the more local trends and have harder blades that can sometimes cut through bones if needed. Since their blades are thicker, they won’t allow the same sharp edge you can find on a Japanese knife.

Japanese blades degree angles: 15-16 degrees

Western blades degree angle: 20 degrees

This makes the Western-style knives a bit more durable and resistant to a more “barbaric” style of cooking. So, if you like to eat perfect, translucent cucumber peels made into roses for breakfast, then you might want to look for a Japanese knife.

If your knife is meant to cut through a whole chicken and barricade your door in case of a zombie apocalypse, you should opt for the Western styles.

Stamped knife vs forged knife

A common marketing gimmick is boasting knives as “forged’ to extract more money from the average, honest citizen. Let’s take a look at the main difference between stamped and forged knives so you can determine which one deserves your hard-worked cash.

A forged knife is a tool made by hand through the centuries-old process of forging metals. The materials are melted, then poured into a cast. Then, a knifemaker will give the blade its shape, let it cool, and further refine it until it looks like something you can use for cutting quesadillas.

Stamped knives, on the other hand, are made with CNC machinery, which cuts the desired shape out of a sheet of metal. Think cookie cutters, but for very dangerous items. Now, on a first look, it’s obvious why forged knives sound like they’d be better quality.

Back in the day, forged knives were the only option available because people did not have access to the CNC machinery needed to mass-produce them. This option became available at the end of the 19th century. And as it happens with most technologies, the first steps weren’t actually reliable.

This changed over the years, as modern CNC machines became stronger, faster, and more precise. As of today, there are few insignificant differences between a forged knife and a stamped knife.

In fact, many craftsmen use CNC to cut blades that they later refine by hand to create exceptional quality knives. If you’re on a budget, you shouldn’t let this myth scare you into buying something you don’t need. Modern stamped knives are reliable, strong, and precise. If you have the money to spare, you should look into buying a tool that’s a better fit for your particular cooking style.

Blade material

What’s a knife other than a sheet of some sort of metal sharpened into an edge that can cut food? I will spare you other philosophical considerations, but you need to remember that the most important aspect of your new chef knife is the material used for the blade.

Chef knives are made from a myriad of materials, but the most popular ones are carbon steels, stainless steel, and ceramic. Here’s a quick rundown of all of them, so you can better understand what you need for your kitchen.

High carbon steel

High carbon steel blades are an exquisite option for people who have the time to care for them properly. They are very durable, very easy to sharpen, and they keep their sharp edge for longer times than most other materials. In itself, this material is just a type of steel infused with high carbon content. This makes the material quite reliable and hard, but hard materials are also a bit more brittle. So maybe stay away from this material if you tend to drop things a lot.

Handpicked for you

True cutting power in the palm of your hand

Pros:

- Harder than stainless steel, which means they can be sharpened into razor-sharp edges.

- Their edge retention is excellent.

- They are easy to sharpen, even if you don’t have experience doing that.

- Very strong and durable, granted you don’t let them chip.

Cons:

- Not resistant to heavy impacts, which can easily chip the blade.

- More susceptible to rust than stainless steel.

- Come at a high price point.

Stainless steel

Stainless steel is a type of alloy that has been infused with a high percentage of chromium, which makes it resistant to water and humidity. For this reason, stainless steel has become the most popular option for knives and cutlery. Tools made out of this material can be used in any environment. They are a great option for people who want a tool that’s reliable but doesn’t need a ton of attention.

Pros:

- They are corrosion and rust-resistant, which makes them a great choice for daily use.

- They can hold their edge for a long time, although high carbon still wins the race.

- They are durable and can resist beautifully to shocks and heavy impacts due to their flexibility.

- They are a lot more affordable than high carbon content blades.

Cons:

- They lose their sharpness faster than carbon steel blades.

- They take much more time and effort to sharpen when they become dull.

Ceramic

Out of all the materials we’ve discussed today, ceramic blades are definitely the hardest. They keep their sharp edge for a really long time, surpassing any metal counterparts.

Ceramic knives aren’t susceptible to any corrosion or rust, and they don’t retain any odor. They are a great alternative for people who don’t have the time to maintain a steel blade against rust constantly. You must keep in mind that they should never be cleaned in the dishwasher. They are also effortless to chip because their hardness makes them equally brittle.

Pros:

- Ceramic knives are lightweight and cause less fatigue for people who spend a lot of time using them.

- They are easy to clean and won’t hold it against you if you forget them in the sink for a while.

- They feature the best edge retention, except for some specialty material knives.

Cons:

- They can be very brittle, so they need to be handled with care.

- It can be challenging to cut meat with them, in some instances.

- They are almost impossible to sharpen. You need to take them to a professional if the blade gets dull.

Handle material

Enough with the blade for one second, and let’s focus on your fingers for a little bit. You like them, right? They’re pretty useful. Well, if you’d like to keep them in full formation, it’s vital to choose the right handle for your chef’s knife.

The handle plays a huge role in the performance, feel, and safety of the knife, and it can also impact the level of fatigue you experience when using it. The most important factors to consider when choosing the perfect handle are material and design, but those are pretty vague. In turn, here is what I want you to look for when choosing a handle:

- The level of movement control it allows you.

- How well you can grip it, especially when wet.

- How resistant it is to water and high temperatures.

- How well it binds to the blade for maximum durability.

Generally, handles come in one of three material options: natural, synthetic, or metallic. I’ve included a list of pros and cons for each of them below.

Natural handles

Natural handles are generally made of different types of wood. Wood has been used since the dawn of type for this purpose since it is reliable, durable, and relatively inexpensive. Some handles are made out of pure, natural wood, while some are injected with a type of plastic or resin that acts as a stabilizer, so it won’t rot with excessive moisture.

Other knives can feature handles made out of Micarta, which is made with a type of resin (not epoxy), bone, or even mother of pearl, which is a substance extracted from oysters. But most chef’s knives rely on the good, old-fashioned wood for this purpose.

Pros:

- Variety of designs, models, types of wood.

- Elegant appearance, potentially collectible depending on the type of wood used.

- Comfortable to hold.

- Durable and reliable.

- Optimum grip, even when wet.

Cons:

- Their porosity makes them susceptible to water damage if they are not water-resistant by design.

- They can become harder to clean with time, as they can crack, scratch or dent easily.

- Some cheap handles can splinter.

Synthetic handles

When referring to synthetic handles, I mostly mean carbon fiber. This makes the handle exceptionally durable while also keeping it pretty lightweight. The carbon fibers are usually woven with plastics to make the handle more durable.

Another option people are raving about is the ZYTEL material, which is a trademarked material owned by DOW Chemical Company. They are practically indestructible but, naturally, come at a high price point. We will focus on carbon fiber handles this time, but feel free to research ZYTEL further.

Pros:

- Strong and durable construction that is built to last for many years.

- High tolerance to heat.

- The lack of metal means no rust or corrosion.

- Very lightweight, a great way to avoid fatigue when working extensively in the kitchen.

Cons:

- It can be pretty brittle when facing heavy shocks.

- The grip might be low, depending on the design.

- Generally more expensive than natural materials.

Metallic handles

Lastly, some handles are made out of various types of metals, with the most common ones being aluminum, titanium, and stainless steel. The main difference between them is durability and weight. All of them are durable and impact-resistant. And all of them are temperature-sensitive. But the lighter the handle is, the easier it is to scratch or dent it.

For example, an aluminum handle will give you the best handling because it is the most lightweight. But a stainless steel handle will be the toughest to break, dent, or chip in any way, even though it will be a bit harder to lift off the counter.

Here’s what you can expect from a metallic knife handle.

Pros:

- The most durable construction.

- Highly resistant to rust and corrosion.

- Excellent weight balance between the blade and handle, especially with longer blades.

- Very easy to maintain.

Cons:

- Decreased grip, depending on contour and texture.

- It might become slippery when wet.

So, which one is the best option for you? Well, like most other Internet experts, I cannot be the judge of that. It will depend on your cooking style and what you want to do with your new chef’s knife. If you’re spending a lot of time in the kitchen, you might want to opt for a handle that reduces hand fatigue and is easy to clean.

If you just found out about your cooking passion during the lockdown, you should probably consider safety first.

What’s a bolster, and do you need one?

“Bolster” is a term you’ll hear a lot when shopping for kitchen knives. There’s a whole online debate over the necessity of a bolster. Needless to say, people can get really heated over it. There’s a special kind of serenity that’s only available to people who don’t know what a bolster is.

Let me ruin that for you.

A bolster is the section of the knife made out of thicker metal that sits between the blade and the handle, cuffing the metal of the blade. They can be made of the same material as the blade or a different one, and they can be more or less prominent.

Its main purpose is to help the stability of the blade, keep it from breaking at the handle and protect your hand from slipping onto the blade when working with slippery foods.

A good quality knife should already be pretty sturdy, so it wouldn’t need the addition to protect it from breaking. But when it comes to safety, bolsters can be a nice feature to have.

Plus, the extra material will add some weight to the knife, shifting its center of gravity from the end of the handle further down the blade.

This makes the knife more ergonomic and easier to handle. Not to mention, it will help your hand from getting tired too fast.

Obviously, it’s not all sunshine and rainbows. Bolster knives come with a particular disadvantage that you should know about. A bolster knife will be significantly harder to sharpen near the handle end, especially when using a whetstone.

If you thought, “oh, that’s not a problem, I never sharpen my knives,” then I warmly recommend this article for your lazy consideration. Trust me; you need it.

For easier sharpening, you can thin or remove the bolster so it won’t bump into the whetstone or consider having your knives professionally sharpened. You know, if you’re rich.

Additional considerations

The Rockwell scale

When shopping for knives, you will often see that the product descriptions contain a number and the letters “RC” written after it. This is the knife’s Rockwell rating, which is a standardized scale used to measure the hardness of a material. So you should just choose a knife with a higher number on this scale, right? Wrong.

There are many considerations that go into determining the Rockwell rating, but you need to keep two things in mind. Softer steels lose their sharp edge faster than harder ones, but they are less likely to chip. They are rated somewhere between the 54-56 RC range.

In turn, harder steels have better edge retention, but they can be damaged more easily by shocks and heavy impact. They are usually somewhere between 52 and 55 RC.

Full tang or partial tang

Ever bought a shiny new knife just to get home and discover the horror of its blade not continuing up to the end of the handle? Me neither. Full tang versus partial tang is a battle as old as the bolster/no bolster one. The best choice depends on personal preference.

A full tang knife is one where the blade’s material ends at the end of the handle. The actual handle is, then, made out of two slabs of grip materials, fixed onto the blade’s tang with a few rivets.

On the other hand, a partial tang is exactly what you expect it to be. The blade continues into the handle slightly, secured with pins or epoxy adhesive. Or both. For a well-constructed blade, a partial tang does not mean the knife will break easily. So don’t let anyone sell you a full-tang for that sole purpose.

For an everyday knife, a partial tang is sufficiently strong, makes the handle completely water-proof, and keeps its weight on the lighter side, so you can use it for prolonged periods with less fatigue.

Good chefs take care of their tools

After spending some cash on a good quality knife, the last thing you want to do is damage it by not taking care of it properly. One of the biggest mistakes people make regarding their knives is not using their cutting board. Those should be made out of soft wood varieties and used every time your knife comes out of its block.

Usage & Cleaning

Yes, I do understand it’s just as easy to cut tomatoes on a ceramic plate, and you don’t want to have to clean the cutting board again. But the cutting board was designed especially for keeping your blade’s edge in top condition. If you use the knife on any other surfaces, like metal, ceramics, plastics, or whatever your countertop is made of, you will probably need a new knife pretty shortly.

Cleaning and hand drying your knife with a paper towel immediately after use is also a great idea. You should never leave it floating around in the sink, and you shouldn’t use it in the dishwasher. This will help your tool rust or corrode faster, while the high temperatures in the dishwasher can sometimes melt the adhesives keeping it together.

Storing & Maintenance

When your knife is completely dry, you will need to store it by snapping it on a magnetic wall strip or sliding it into a knife block that was designed specifically for its shape and size. When the knife is in, its tip should have the slightest bit of space before it reaches the wood.

Some people like to give their knives a slight sharpening by sliding them on a honing rod after each use. I feel like that’s a bit over the top, but feel free to do that the first few weeks, fueled by the excitement of your new purchase. Generally, depending on the type of metal used, you’ll want to sharpen your knives using a manual or electric sharpener every 1-2 months.

Final words

So, what did we learn today? Well, I hope we learned that the best chef’s knife is the one that handles your personal requirements the easiest. I know, I am not reinventing the wheel here. But it’s useful to remember that there is not a single, cookie-cutter best chef’s knife that will improve your life.

The best chef’s knife, for you, could be the exact same knife that enthusiasts are making fun of on cooking forums. As long as it complies with your cooking style, gives you optimal protection, and is, itself safe from your lack of dexterity, then you probably found your one.