As the name suggests, the Rockwell hardness scale is a way to measure a material’s hardness. It’s the industry standard for measuring the hardness of materials like steel, aluminum, copper, and more. It has certain applications to knives as most kitchen knives are made from steel.

When the materials change, so does the testing method. That’s why there isn’t a single type of Rockwell hardness testing. The test method that concerns knives is Scale C, also known as Type C. This scale is for steel, titanium, hard cast irons, pearlitic malleable iron, and more.

In this article, you’ll learn everything about the Rockwell hardness scale for steel, along with what it means for kitchen knives.

Table of contents

What exactly is the Rockwell scale?

With the steel industry having different uses, from your kitchen to the construction of buildings to aerospace to the cars we drive, there is a need to measure hardness to ensure that it’s at the precise point for the purpose intended. The Rockwell hardness test delivers just that.

What does the Rockwell scale mean for steel and kitchen knives?

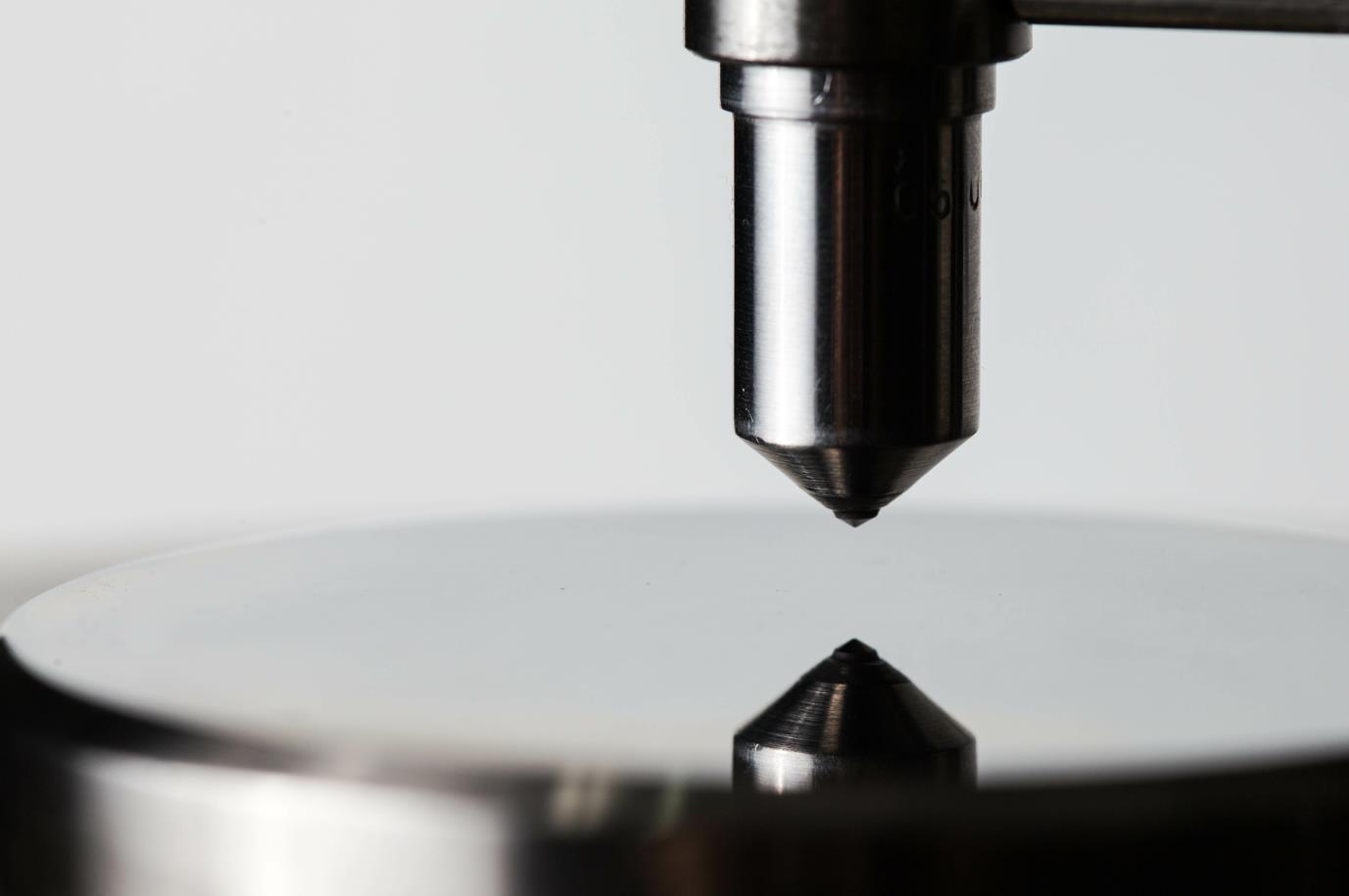

The Rockwell scale works by measuring the permanent depth created using an indenter with a specific amount of force. There are different scales; thus, indenters and force applied to the materials change. Scale C for steel uses a diamond indenter as it’s one of the hardest materials known. The indenter pushes on the steel with a total force of 150 KGF.

In the packages of most kitchen knives, the Rockwell hardness rating for steel is stated by HRC (Hardness Rockwell Scale) or RC, followed by a number stating the hardness and the last letter expressing the type of testing.

While hardness is vital as harder steel will hold a sharp edge for longer, it doesn’t always indicate the qualities to look for in a kitchen knife. The harder the steel gets, the likelihood of edge chipping increases. That’s why it’s essential to find the proper range for kitchen knives and decide on softer or harder steel based on your habits and preferences.

How does the Rockwell hardness testing work? (Scale C)

The Rockwell hardness test is done by measuring the permanent depth created on a material caused by the force of the indenter. A rounded diamond cone indenter is used for steel as it falls under Scale C, where the 150 KGF of pressure is applied for a particular amount of time. Here is a brief explanation of how the Rockwell hardness test calculates the hardness of a piece of steel.

- The steel is placed under the indenter with a starting force of 10 KGF. The depth created with the first force is measured and taken as the first reference point.

- A secondary force of 140 KGF is applied to the steel and held for a period, adding it to a total of 150 KGF.

- The secondary force is removed from the steel while the initial pressure remains active. The depth with this force is taken as the second reference point, and it is the permanent depth created.

- The depth between the first and second reference points is then measured to figure out the HRC rating.

In simpler terms, the permanent depth created by pushing the indenter into the steel using a specific amount of force; in this case, 150 KGF reveals the Rockwell hardness rating. That’s, of course, with the help of a bit rather complicated math and precise measuring.

Because the hardness is a vital point to determine certain qualities in any metal, dedicated machines perform the Rockwell hardness test.

What is the RC rating?

The RC rating tells the hardness of the steel, but there are also different ways this is shown. Other than HRC or RC, you can see the hardness stated on the packaging of kitchen knives as Rc, HR C, HRc, or simply as C.

They all refer to the same regardless of the letters. What to look for is the number, as it’s what showcases the steel’s hardness.

RC numbers meaning

The higher the RC rating, the harder the steel and vice versa. The hardness of the steel can tell a lot if it’s going to be suitable for the tasks you have in mind. For example, if you’re planning on purchasing a cleaver for some heavy-duty work like cutting through meat bones, you wouldn’t want it to come with extra hardness as harder steel is more brittle.

What does the Rockwell hardness scale mean for kitchen knives?

Before anybody purchases a knife to use in the kitchen, considerations like edge retention, sharpening ease, the tasks performed, and pretty much anything that involves preparing ingredients will be a consideration.

The RC rating can tell if a kitchen knife will be a good pick as there are certain things that the hardness of the blade affects directly. How well the edge lasts has a close connection with the hardness. If it’s harder, it will hold a sharp edge for longer. If softer, you will need to pick up a whetstone to sharpen more frequently.

However, it also means that the harder the blade, the more challenging it is to sharpen it due to increased wear resistance. You’ll need to spend more time sharpening the blade using a whetstone or another sharpening tool to give it an excellent cutting edge. That’s why honing is especially important for knives with harder blades to make the edge last longer.

Additionally, harder steels are typically more brittle. Similar to ceramic knives, the increased hardness in steel can result in chipping or even shattering if it’s too hard. Having all this said, there is no such thing as high hardness equals good or low hardness equals bad. It boils down to the knife’s purpose and the cook’s preferences.

Handpicked for you

True cutting power in the palm of your hand

Choosing a knife with the appropriate RC rating

Unless you prefer one over the other, there isn’t really an ideal HRC rating. If you like your knife to be sharpened easily and use it on heavy-duty works, a knife with an RC rating of around 54 to 56 will be a better choice. However, most professionals prefer their knives’ hardness at around 58 HRc for better edge retention.

Additionally, the knives with a lower RC rating aren’t likely to chip – even if they fall on their edge to an undesirable surface or you store them incorrectly. There isn’t a need to worry about kitchen knives with lower HRC ratings chipping as they aren’t brittle enough.

A chef’s knife with an RC rating above 60 will hold its edge superbly while being a little challenging to sharpen. It’s the opposite with kitchen knives with a softer hardness rating. The hard knife blades are surely a lot more fragile due to increased brittleness than knives with softer steel, but with enough care and caution, you’ll have them in excellent condition for years.

Though some steel has a typical hardness range, any steel can be tempered to lower and higher numbers. However, there can only be so much flexibility. Suppose you want a Japanese knife, like gyuto with Japanese steel; the typical hardness will be between RC 58 and 69. The typical Japanese steel won’t be ideal if you wish to have a softer blade. Instead, a softer steel like the 420 steel would be the better choice.

Frequently asked questions

How to use Rockwell hardness tester?

How you’re going to use the Rockwell hardness tester depends mainly on the machine. The automated Rockwell hardness testers don’t require any work. Just assemble the indenter and run it. For manual testers, you first need to set up the tester securely, apply the minor load, set the barrel dial, and apply the load. Then, take the reading, and you’ll see the results.

Is the testing destructive?

The Rockwell hardness test is considered non-destructive. It won’t damage the material tested, but there will be a tiny bit of dented part that’s about one to two millimeters in diameter. Depending on the color of the material tested, this can go unnoticeable.

How to test Rockwell hardness at home?

The Rockwell hardness test is performed using special machinery built only for this purpose. Unless you have a way to center a total of 150 KGF of force into a piece of steel and measure the depth, you can’t perform the Rockwell hardness test at home.

What is the best Rockwell hardness for a chef’s knife?

As explained in this article, there isn’t a specific best hardness rating. Most of this depends on preferences. You’ll need to use a knife for some time and assume whether it’s made from hard or soft steel. The easiest way to figure this out is edge retention and the ease of sharpening. If the knife holds its edge for long but is stubborn to sharpen, it’s likely from hard steel. If the other way around, it’s made from softer steel.

Conclusion

To summarize everything mentioned in the article, there is no magical Rockwell hardness number to look for in a kitchen knife. Choosing a knife with hard or soft steel, like the majority of the other things in the kitchen, comesdown to personal preferences.

If you don’t know which is better for your cooking style and habits, consider a knife with an RC rating between 54 and 56. A hardness rating around this range will ensure that the steel is suitable without being too soft or hard.