If you’ve ever had the chance to watch a cooking show or competition, you’ve probably seen the chef expertly running his knife against a sharp, steel rod several times over. You remember a similar tool stashed away in your cutlery block and wonder, what purpose does it serve anyway?

The sharp steel rod that you own is called a honing steel. But what’s a honing steel? And how do you go about using one?

What’s a honing steel?

A honing steel or rod, also known as a sharpening steel, is basically a rod that is steel, ceramic, or diamond coated, used for the purpose of re-aligning knife blades. Honing steel allows your knife to feel sharper by pushing the knife edge back into its prior position, without actually sharpening it.

While a honing steel is also called a sharpening steel, it does not actually sharpen a knife. A knife sharpener sharpens a knife, while a honing steel, well, hones.

Table of contents

Differences between honing and sharpening

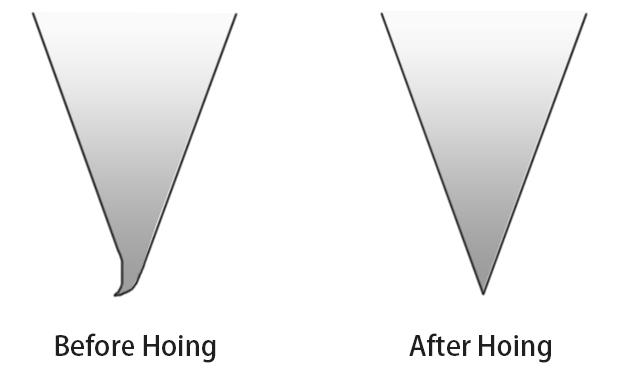

Whether your knife needs honing or sharpening, depends on the condition of your knife blade. Look closely, is the edge of your knife blade bent or has the sharp edge been lost altogether? If the sharp edge is gone, your knife needs sharpening. If the edge is simply bent or misaligned, your knife needs to be honed.

Honing allows your knife edge to be pushed back to the center and be realigned. This in turn allows the knife to feel sharper. On the other hand, sharpening a knife basically involves removing some material from the knife blade’s edge, for producing a new and sharp knife edge instead.

| Honing | Sharpening | |

| Purpose | Re-aligns the existing knife edge | Produces a new, sharp knife edge |

| When to do it | When the knife edge is bent or misaligned | When the sharp knife edge is lost |

| Material | No material is removed from the edge | Material is removed from the edge |

| Frequency | Done regularly, often after every use | Done occasionally, probably once or twice a year |

| Tool used | Honing rod/honing steel | Manual sharpener, electric sharpener, or whetstone |

Below is an image of how a knife edge looks like before and after it has been honed

Types of honing rods

Honing steel rods are mainly of three different types, namely steel, ceramic and diamond. However, the latter two honing steels merely signify the top coating on to the basic steel core. Here is a brief description of each type, along with pros and cons so that you can make an informed decision when buying one.

Steel rods

The fact that steel is abundantly available makes steel honing rods one of the most classic, commonly found rods out there in the market. These rods are widely manufactured in long and thin structures, with ridges running across its entire length.

Steel honing rods are preferred by most chefs due to their hypoallergenic nature as well as their anti-rust properties. Moreover, many models are now coming with magnetized features that allow collection of microscopic steel pieces of the knife blade when honing. This allows your food to remain free from steel particles.

Such steel rods also offer greater durability than other honing steel types. However, you need to be careful when honing knives made up of harder steel. This is because harder metal tends to be more brittle and thereby more prone to breakage during the honing process.

Pros:

- Affordable and reliable

- Durable

- Magnetized feature offers collection of microscopic particles

Cons:

- Harder to clean because of microscopic particles on steel

- Rough on knives

- Regular honing dulls blades

Ceramic rods

We know we said that honing rods don’t take material off the knife edge, but this type shaves a little to achieve a sharper knife. Taking off such miniscule bits allows your knife to slice and cut as it used to the day you bought it.

Ceramic rods are also known for their heat and corrosion resistant properties, are lightweight and easy to use. Available in various sorts of grits, the ones with coarser versions are meant for increased friction while finer ones are intended for delicate blades. It is important to note here that ceramic rods are not ideal for honing purposes, and will impact the knife’s durability in the long run.

Also, these rods are delicate and may break upon falling. Ideally, these rods can be used on Japanese knives as well as knives with steels that are not too hard.

Pros:

- Heat resistant

- Corrosion resistant

- Ideal for Japanese knives and other delicate knives

- Enhanced precision

Cons:

- Delicate and prone to breakage

- Comparatively more expensive than steel

Diamond rods

Another honing steel that performs double duty as a knife sharpener is the diamond honing rod. These rods can handle any knife that comes their way, but make sure you don’t end up honing everyday with this tool or you won’t have any blade left for honing anyway.

That being said, you can use a diamond honing rod if your knife blade has gotten dull and you can’t perform an actual sharpening session on it right away. Moreover, the diamond coating on such rods removes more metal than ceramic, and many users complain of the diamond falling off or wearing away too soon.

Pros:

- Sharpens as well as hones

- Buys you time before an actual sharpening session

- Reliable

Cons:

- May take too much material from knife edge

- Diamond coating wears off or falls off too soon

- Can’t be used for honing regularly

- Takes practice to hone, otherwise will damage the blade

How to hone a knife

The next thing we are going to help you learn is how to hone a knife. Honing a knife begins with finding the right angle that the knife is being sharpened at.

Steps

- Use a cutting board and position the honing steel vertically, perpendicular to the board.

- Position the knife at the most appropriate angle to the honing steel. For most western knives, it is usually 20 degrees. For approximating a 20 degree angle, bring the knife blade close to the honing steel at a 90 degree angle, and rotate the knife twice by halving the initial angle. This will position your knife blade to 22.5 degrees. You can tilt the knife a little more to approximate the 20 degrees.

- Begin by placing the knife at the base of the blade, at the top of the honing steel.

- At the right angle, allow the blade to slide down as the knife pulls towards you.

- At the opposite side of the steel, do the other side of the knife.

- Swipe back and forth, two or three times each.

Tips

- Hone at the angle that you sharpen your knife at.

- Maintain the angle while honing.

- Don’t let the knife tip slide down the edge of the honing steel, else it may become rounded.

- Make sure that you’re not pressing too hard, the pressure should be a little more than the weight of the knife.

- Don’t over hone. 3 or 4 swipes are enough for honing.

Still unsure about how to use a honing steel? Watch this video to help you out:

How to choose a honing rod

There are many types of honing steels available in the market, depending on their brand, length, material, price, and several other factors. The following factors must be considered before you purchase a honing rod for your knife.

Length

It is important to consider what length of the honing steel you are buying, as it impacts on what knives can be honed on it. As a rule of thumb, consider buying a honing steel that is the length of your longest knife, if not longer.

Honing steels with longer lengths ensure that your knife has a consistent edge when honed.

If you own knives that are longer in length, you should consider buying a longer honing steel, so that your knives can be easily honed on them. Likewise, shorter knives need shorter honing steels of around 8-9 inches. Longer steels can be around 10-12 inches respectively.

Material

As discussed earlier, there are three kinds of honing steels out there in the market: steel, ceramic and diamond.

The most common honing steel is stainless steel. Many chefs prefer this honing steel since they are good to go for most knives. They remove microscopic material from the knife edge and straighten any blade that comes their way.

Ceramic honing steels act as honing steels as well as sharpeners, taking away more metal than stainless steel. These steels are brittle and need additional handling care.

Lastly, diamond honing steels act similar to a knife sharpener and remove considerable metal from the knife blade. This means you can’t use them regularly and are not true honing steels.

To conclude, choosing a honing steel is impacted by the purpose you need it for. If you are looking for a steel for your regular honing sessions, you should go with stainless steel ones. If you’d like to shorten your trips to the knife sharpener, you might want to buy a ceramic or a diamond one.

Handle

Choose a handle that allows you to keep a firm grip on the honing steel. Firm grips keep the steel from slipping and doing damage to you and your knife.

Price

The most economic honing steel is the stainless honing steel. This is because steel is abundantly available and makes this material cheaper than other types of honing steels.

Ceramic and diamond ones are more expensive than steel, so you should weigh your pros and cons before making a final purchase decision.

Should you hone a Japanese knife?

We have often seen people coming in to professionals with their damaged Japanese blades after a failed honing session. This brings us to the question: should Japanese knives be honed? Experts say there are two questions that must be asked when honing Japanese knives:

The first issue that must be addressed when honing a Japanese knife is whether the knife is single or double beveled. With single bevel knives, it’s usually advised not to hone since the blades are sharper and therefore, more delicate. Double beveled knives can be honed, but should be honed at a sharper angle than German knives (11-15 degrees).

The next important factor to consider when honing a Japanese knife is the kind of steel its blade is made of. Traditional Japanese knives are made of high carbon steel which makes them delicate and prone to chipping. Therefore, they should only be sharpened with a water whetstone.

Handpicked for you

True cutting power in the palm of your hand

On the other hand, contemporary Japanese knives are made with modern steels (such as VG-10) that offer more robustness and therefore, can be honed.

Finally, when it comes to honing Japanese knives, our vote is with ceramic honing steels, since these steels offer particularly fine grits and hardness that is best suited for Japanese style knives. Moreover, this is the only viable option for your Japanese knives.

Using other types of honing steels might result in chipping and ultimate damage to the blade.

How to clean a honing rod

Your regular honing sessions might have turned your honing steels into a blackish or grayish color. This dirt that has built up due to tiny metal particles is known as swarf, and indicates that your honing steel is dying for a cleanup.

As a rule of thumb, your honing steels should be cleaned up after every honing session. Use a dry cloth to wipe it after you have honed your knife. Occasionally, you should also use a damp cloth with vinegar to scrape off the swarf.

If you haven’t been cleaning regularly, however, your honing steel might be begging you to wipe it clean. When this happens, it’s best to use honing oil. Honing oils allows metal debris to loosen up and makes your cleaning task easier.

All you have to do is pour some oil on the steel and allow it to loosen up the material. Once done, scrub off the debris with a sponge or scrub. Be careful not to scrub too hard though, or you’ll end up ruining your honing steel.

Conclusion

This was all about honing steels. We at HDMD hope that you found this article useful when honing your dull edges back to their razor sharp forms. Visit our blog post Why and How to Hone a Knife to find out why it is important to hone your knives on a regular basis.