There is more to knives than what meets the eye. Even when closely examining the blade, it’s nearly impossible to see certain features right away. The knife grind fits this description perfectly.

A blade is a piece of hard material, typically steel, that’s too thick to cut through anything. The edge is what cuts the ingredients, and how it does it can change entirely depending on how it is ground.

Knives are such universal tools that everybody uses. Because there are a variety of tasks performed with them, knifemakers ground the blade differently to make specific cutting needs easier. These various ways of creating the edge are known as knife grinds.

Although a small detail, the knife grind gives many attributes and functions to the blade. Appropriately choosing the knife grind with the right blade design will build the perfect cutting tool.

This detailed article will explain everything you need to know about different knife grinds.

Table of contents

What is the knife bevel?

To better understand different types of knife grinds, we first need to cover the bevel.

The bevel refers to the part of the blade where it begins to get thinner before reaching the edge. It’s a general term for where the blade is ground. For example, a common expression used for giving more detail to blades is single bevel and double bevel. Single bevel knives are ground on only one side, while the other on both sides, hence the names.

However, there are sort of levels to knife bevels, indicating where it occurs. Starting from the spine to the edge, these are blade bevel, edge bevel, and apex bevel in order.

Here is a short explanation of these.

- Blade bevel: The initial bevel where the blade gets thinner than the spine.

- Edge bevel: The thinner bevel than the blade bevel that supports and helps push food away from the apex bevel.

- Apex bevel: The blade’s edge, where it makes contact and cuts the object.

While these are the bevel of a knife, the different places and angles knifemakers ground the blade to form them are what we call knife grinds.

Handpicked for you

True cutting power in the palm of your hand

Types of knife grinds

Where the bevels are ground and at what angle changes, so does how the knife cuts. Since this is perhaps the most critical aspect of a knife, the grind type has significant importance.

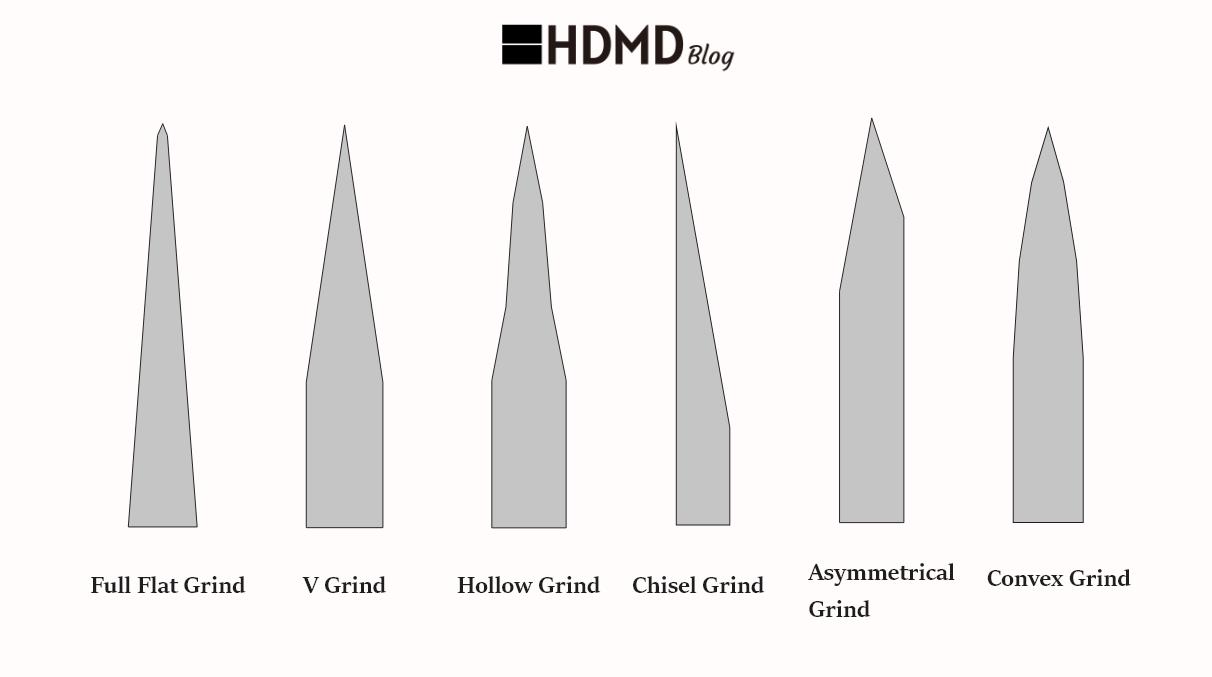

Some knife grinds are more popular than others for their convenience; some serve a specific purpose. Regardless, here are the primary types of knife grinds, their advantages and disadvantages, and how they change the way the blade cuts.

Flat or V grind

The name flat grind can mislead anyone if taken literally. The knife would be far from anything sharp if the blacksmith grinds the blade completely flat! Luckily, we also refer to this knife grind technique as V grind, as it’s essentially an almost V shape.

Just as there are two names for this knife grind, it comes in two forms.

Full flat grind

There is no blade bevel in a full flat grind knife. The blade begins to get thinner, starting from the spine until the edge. The apex bevel is ground right before the edge surface, impossible to see with the naked eye.

This makes the general thickness slimmer but with enough material to be durable at the spine and blade’s mid to top areas. The full flat grind blades are both good slicers and choppers that can endure some hard use. Overall, this knife grind type makes the blade sturdier than much slimmer alternatives like the hollow grind while allowing it to slice finely.

V grind

Take everything the same as the full flat grind and apply it to the V grind, except where the blade first thins down. Instead of the blade getting slimmer from the spine, it tapers near the edge.

The V grind ultimately gives a sturdier blade that can handle impact better. Even though you should only cut dense ingredients like bones with the appropriate knife, a V ground knife will be more suitable for robust work than another with a full flat grind. The V grind blades aren’t as susceptible to chipping when occasionally cutting small poultry bones compared to its alternative.

Whether V grind or full flat grind, flat grind edge can have a variety of thicknesses. There is no set standard for it. The thickness can change depending on the blade design and the knife’s purpose.

Pros

- A versatile grind type, the thick blades tend to be better at chopping and slim ones at slicing.

- Offers easy control to most cooks that don’t require special skills.

- Easy to make by knifemakers, doesn’t bring added costs.

Cons

- Depending on the thickness, it can make the blade flimsier.

- The apex edge tends to lose its sharpness quicker than others.

Hollow grind

The hollow grind and full flat grind are similar, or at least the principle behind how the knife is ground. They are both ground from the spine to the edge, but as the name suggests, the hollow grind has a more or less concave design to it. Additionally, knifemakers can create the hollow grind in different blade parts, just like the flat grind. These are known as a full, partial, or half hollow grind.

The hollow grind makes blades have less material in the blade bevel, which is what supports the edge surface. It even gets thinner at the apex bevel, the cutting edge.

The extremely sharp yet thin edge makes hollow ground blades a lot more fragile compared to others. Because of this, knives with a hollow grind shouldn’t be used with force or for cutting dense ingredients. Otherwise, it can chip unexpectedly or roll over, requiring repair to fix the edge in the end.

Needless to say, this grind is perfect for complementing a slicing knife. It becomes effortless to slice the knife through ingredients. The overall thin blade helps push foods. Cutting anything soft, like boneless animal protein or tomatoes, feels like a hot knife through butter combined with a sharp edge. As you’d expect, this knife grind is more fitting for slicing knives, like the Japanese sujihiki.

Pros

- Delivers an incredibly sharp edge that glides through ingredients easily.

- The thick blade profile makes it easier to get under rather difficult parts of certain ingredients, like skinning fish, filleting, etc.

Cons

- Not the most durable knife grind, it can chip following improper use.

- Mainly good for slicing, not suitable for chopping, and other general tasks.

Chisel grind

If you know how single bevel knives work, you should already have an idea of this. The chisel grind is only found in single bevel knives, which create its distinct cutting style. The way single bevel knives cut makes them more complicated than others due to the grind.

As mentioned, only one side of single bevel blades is ground. This makes the bevel much thinner than others in this article, enabling it to have a sharper edge. The other side is left flat or has a concave design for better food separation.

What makes the chisel grind different is the way it slices through ingredients. A knife typically goes in a straight line when you press it on an ingredient because it is pushed on both sides. With chisel grind knives – or single bevel knives in general – what you’re cutting is moved towards the ground side.

Since the hand you’re holding the knife will change whether the chisel grind is on the left or right, they aren’t ambidextrous. Knife brands must state if their chisel ground blades are right-handed or left-handed. The right side of the blade is ground for lefties and the opposite for righties.

Pros

- Provides an exceptionally sharp edge that’s perfect for slicing, filleting, and any other intricate work.

- Takes less time to sharpen as it requires it only on one side.

Cons

- Lefties may have a hard time finding their desired blades and custom order.

- Has a distinct cutting angle that requires practice to familiarize yourself.

Asymmetrical grind

The double bevel grinds mentioned in this article have a 50/50 ratio at the edge. While this enables everyone to operate the blades comfortably, there are also asymmetrically ground blades. Think of these as a merger between single and double bevel knives.

The most common ratio in asymmetrical knives is 70/30 though it can lean towards one side more or less than this. Knife manufacturers utilize asymmetrical blades to bring the best out of both worlds into their blades. These knives aren’t entirely a single bevel, but not quite the same as a typical double bevel knife at the same time.

While the asymmetry is apparent in these blades, all knives are asymmetrical to a certain degree. It would take precisely measured grinding to form an entirely even bevel on both sides. Most blades will have some asymmetry since achieving a perfectly 50/50 grind is nearly impossible with even today’s advanced manufacturing.

Tiny differences in symmetry can happen in any blade. When you look at the edge precisely, there are bound to be asymmetrical parts. Yet, these mostly go unnoticed as it doesn’t affect the way the knife cuts. If you catch asymmetrical cutting in a double bevel knife that is supposed to have an even bevel, it should be a complaint rather than a feature of the knife.

Pros

- Provides better food separation.

- More durable than chisel ground blades while having a similar cutting style.

Cons

- Relatively difficult and tricky to sharpen.

- Cutting at the wrong angle can dull the blade quickly and tear the foods.

Convex grind

This knife grind is quite different than others in this article. As you can see, most knife edge types go under a steep angle change. This also applies to convex grind in parts, but the apparent bend only happens at the blade bevel.

As the name suggests, the convex grind is more or less curved. Instead of the edge bevel getting increasingly thinner, the convex grind has a gradual transition between the apex bevel and blade level. Therefore, it has more material at the edge than any other knife grind. While this would undoubtedly make fine slicing a nightmare, it has its use cases.

The convex grind is best for blades that need to absorb impact. For example, it makes the best knife grind for cutting dense bones, fruit pits, and anything dense. The sturdiness of the convex grind ensures the blade will cut without chipping or other damages, making it perfect for cleavers and other heavy-duty kitchen knives.

Out of all the other knife grinds, it’s the most durable but not suitable for every task you expect from a kitchen knife. You can find the convex grind in cleavers and other blades used for cutting through anything rigid.

Pros

- Most durable knife grind.

- Better-suited for chopping large amounts of ingredients.

Cons

- Not great at regular slicing.

- Very challenging to sharpen for a beginner sharpener, but those with experience won’t find it incredibly difficult.

Handpicked for you

True cutting power in the palm of your hand

Japanese knife grinds vs. western knife grinds

Any of the knife grinds mentioned are found in both Japanese and western kitchen knives. However, some are more popular than others. It doesn’t take a lot to understand why certain knife grinds are better for Japanese or western knives than others.

Let’s start with Japanese knives.

Japanese cuisine demands fine slicing across many different dishes. A part of the reason why the Japanese have many specialized blades for slicing is this. Since some of the knife grinds mentioned are better at slicing, like the hollow grind and full flat grind, chefs prefer them more on their Japanese blades than others.

On the other hand, western cooking requires lots of chopped and diced ingredients, from finely chopping vegetables to making sauces and dicing meats for stews. These require a tough blade that can go on chopping for long periods.

Knife grinds that highlight sharpness for slicing is more delicate, so they aren’t as suitable for these tasks. Instead, sturdier grinds like the saber or V grind are better suited for western-style knives. The ones that promote sharpness are better off in Japanese kitchen knives and sturdier options in western style blades.

Lastly, since single bevel knives can only have chisel grind and its variations like added back bevel and urasuki, it’s exclusive to Japanese knives. Good examples of single bevel Japanese kitchen knives are Yanagiba, Deba, and Honesuki.

How to choose the appropriate knife grind?

Choosing the right knife grind is just as important as picking up the proper knife for the task. Most knife brands, including us, will grind the blade according to its primary uses.

As someone purchasing a knife for a specific task like cutting large chunks of meaty bones or slicing raw fish for sashimi, you might benefit from a particular grind type. That’s where you’ll need to look for the blades accordingly.

The verdict

Choosing the proper knife grind for the blades you’re planning to purchase is just as essential to pick the right blade for the duties you’ll perform with it.

Nonetheless, most brands with enough experience will know which knife grind suits the best for the knives they are manufacturing. HDMD Knives brings fine craftsmanship with years of knowledge in hand-forging blades to deliver the best knives.

Read more on our blog to expand your knife knowledge and shop for beautifully crafted handmade kitchen knives at HDMD Store.