Japanese knives have been around for centuries, boasting a long and storied history. Among the most iconic and well-known is the Higonokami pocket knife. You can easily recognize it by its distinctive folding blade, attached to the handle by a single pin.

The Higonokami is a non-locking pocket knife designed with form and function in mind. The design has remained relatively unchanged since its inception over 150 years ago. Knife forgers use simple SK carbon steel to make the blades, which are then hardened and tempered to make them tough and durable.

This article will look at the history, uses, and construction of Higonokami knives and their place in Japanese knife culture.

Table of contents

What is a Higonokami knife?

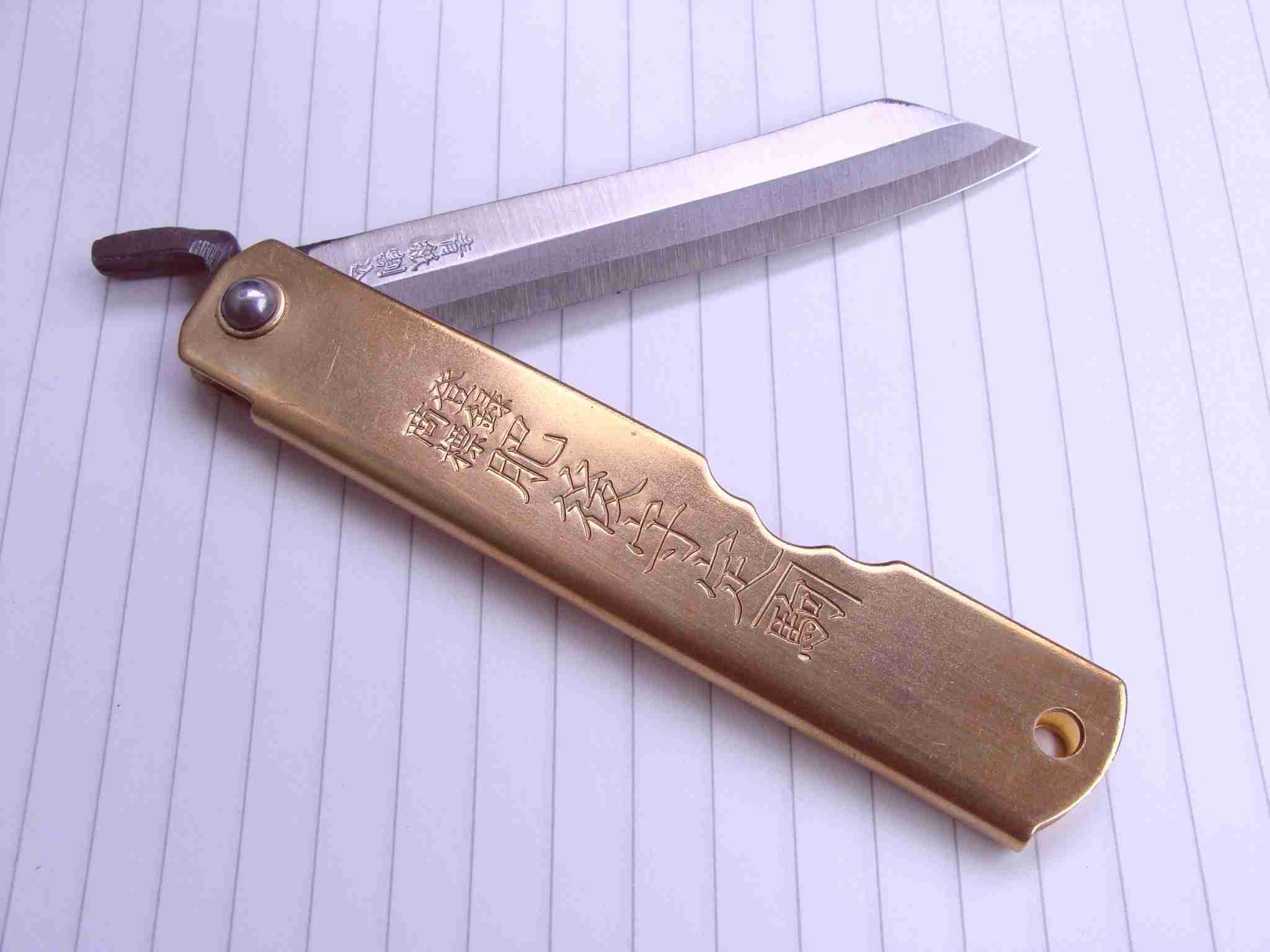

Higonokami is a flat-grind, fixed-blade pocket knife from Japan. It features a metallic folded-over sheet handle construction with a simple pin attaching the blade to the handle. The knife lacks a locking system; however, it uses swivel friction on its iconic level, also known as chikiri.

The friction between the blade and handle makes this knife so unique. It allows for easy opening with one hand, yet it’s still secure enough that it won’t close on your fingers when using it. Some contemporary Higonokami knives feature stylish wooden handles, while others boast stamped steel or typical brass.

History of the Higonokami knife

“Higo no Kami” is Japanese for “lord of Higo.” The knife first appeared in 1896 when blacksmiths struggled with declining demand for swords due to reforms set forth by Emperor Meiji.

Records reveal that a blacksmith named Teji Murakami created the knife prototype by adding a lever to what was before a simple non-locking folding knife design. Some records mention that Shigeji Nagao, another blacksmith from Higo, played a crucial role in developing the knife.

A knife maker’s guild was created in 1899, and in 1907, the corporation trademarked the name “Higonokami.” Only members belonging to the corporation in Miki had the right to manufacture and sell Higonokami knives.

Due to an unprecedented anti-knife campaign and world war two, Higonakami knives lost popularity. However, the knife continues to have a small but loyal following of users and collectors. Today, Motosuke Nagao, a fifth-generation descendant of Shigeji Nagao, is the only remaining legal manufacturer of Higonokami knives.

Features of the Higonokami knife

The Higonokami is a small, flat, and light knife. It typically measures around 3.5 inches long when closed and six inches long when open. The blade is usually between 2.5 and three inches long.

The most defining feature of this knife is its chikiri, the metal lever that protrudes from the butt of the handle when the knife is open. The chikiri serves two purposes: first, it’s used to open the knife; second, in conjunction with the blade, it provides a locking mechanism to keep the blade in place.

The blade features a flat grind with a beveled edge. The grind gives the blade a very sharp cutting edge while maintaining its strength. Despite the simple and elegant design, the Higonokami is a versatile and capable knife.

Parts of a Higonokami knife

The Higonokami has three primary parts: the blade, the handle, and the chikiri.

The blade

The blade is perhaps the most important part of the knife. It’s simple, with a flat grind and a beveled edge. Most designs feature simple SK carbon steel, while others may use white steel, blue steel, or blue lamination steel.

It boasts a sandwich structure which means that a hard steel core is sandwiched between two layers of softer steel. This structure creates a blade that’s strong, durable, and easy to sharpen.

The handle

The handle is simple and elegant, with a folded-over sheet metal construction. The most common material used in the handle is steel, but some designs feature brass, wood, or synthetic carbon fiber.

The handle is attached to the blade via a simple pin, and it features a hole for a lanyard. The chikiri, the metal lever that protrudes from the butt of the handle, is also an integral part of the handle.

The chikiri

While it’s considered part of the handle, the chikiri plays an important role in the knife’s function. The chikiri is responsible for opening the knife and providing a locking mechanism to keep the blade in place. It’s made from steel and is usually flush with the handle when the knife is closed.

Higonokami knife uses

Higonokami’s sharp blade and lightweight design make it ideal for various tasks, either big or small. Below are some of the most common uses for Higonokami knives.

Cutting Fruit

Higonokami knives can easily cut through fruits. The sharp blade can penetrate the fruit’s skin and make clean cuts through the flesh. Moreover, its lightweight design makes it easy to control, which is important when cutting delicate fruits.

Opening boxes

The sharp blade and lightweight design make Higonokami knives ideal for opening boxes. The knife can easily slice through tape and cardboard, making it a handy tool to have around the house or office.

Carving

The sharp blade and lightweight of the knife make it ideal for carving. Whether carving wood or soap, Higonokami knives can easily handle the task. The small size of the knife also makes it easy to control, which is important when carving delicate materials.

Sharpening pencils

Before they became unpopular in Japan, students commonly used Higonokami knives to sharpen pencils. The sharp blade made quick work of dull pencils, and the small size made it easy to control. Nowadays, you’re more likely to see students using electric pencil sharpeners, but the Higonokami knife is still popular.

Is Higonokami a great EDC knife?

The Higonokami has excellent features of an everyday carry (EDC) knife. Its small size and lightweight design make it easy to carry, and its versatility makes it a handy tool to have around. The Higonokami knife can easily handle the task, whether cutting fruit, opening boxes, carving, or sharpening pencils.

However, some challenges with its design make it less than ideal for EDC. First, while the friction folder is simple and elegant, it’s not as secure as a lock-blade knife. Over time the blade may loosen, making it more difficult to control.

Second, the chikiri can be challenging to use, and it’s easy to accidentally deploy the knife when opening or closing. With reduced friction, it may open in your pocket, which can be dangerous. However, you can use a zip tie to secure the chikiri in the closed position.

Different types of higo knives

Note that while there’s only one original Higonokami knife, different variations of the knife have been developed over the years. Below are some alternatives you may want to check out.

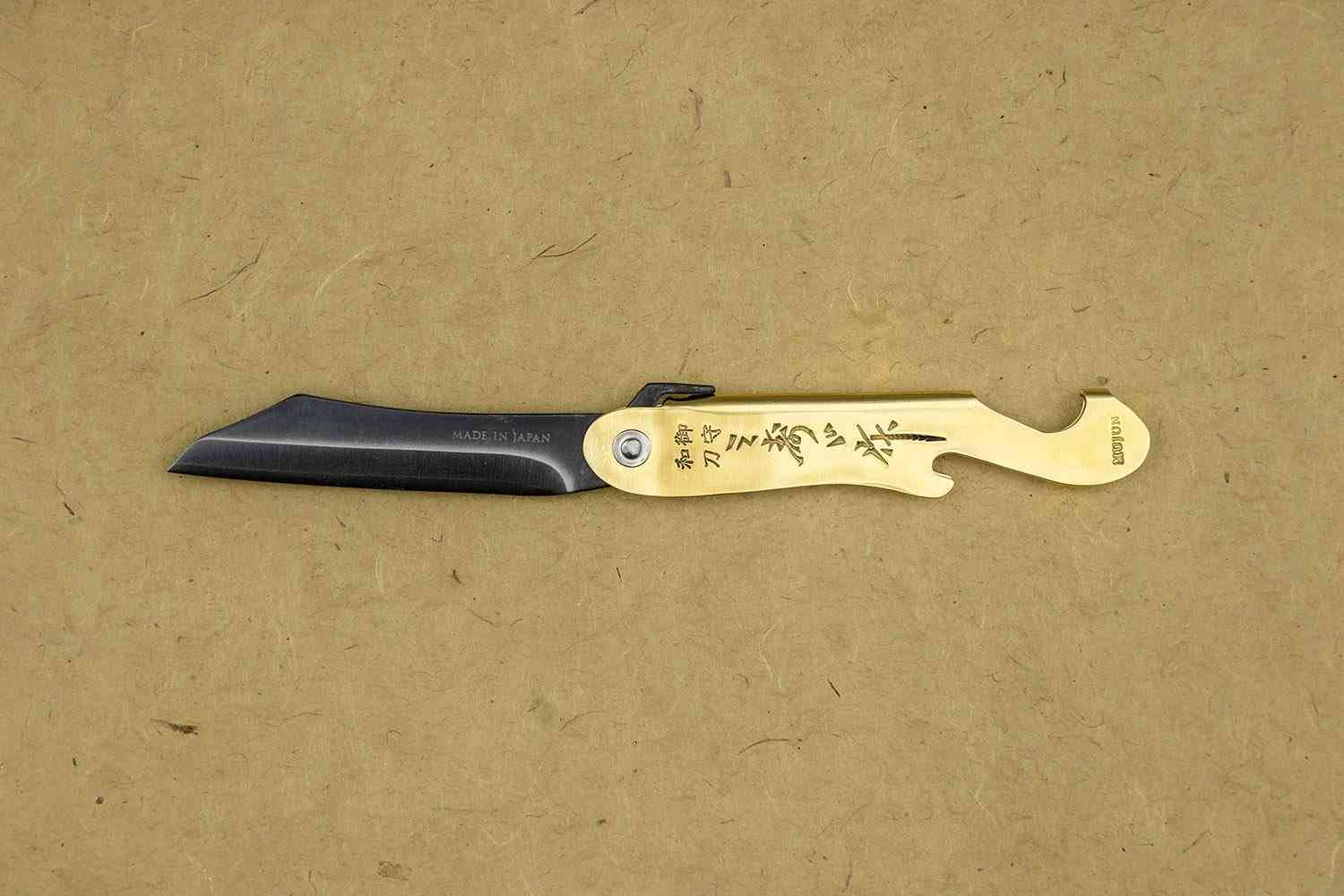

Mujun Fuji Higo

The Mujun Fuji is a modern take on the Higonokami knife. It features an all-brass frame with a hand-forged carbon steel blade. The knife’s design is by a group of young designers based in Miki, Hyogo Prefecture, trying to shed light on contemporary Higonokami knife making.

Seki Kanetsune Higo

Perhaps the most well-known alternative to the Higonokami knife is the Seki Kanetsune. It’s a traditional take on the knife, with a brass handle and a hand-forged carbon steel blade.

The blade incorporates a modern design, such as a repositioning pocket clip for added versatility. With time the brass scales age and patina, giving the knife a unique look.

Closing

The Higonokami is an excellent option when looking for a versatile and easy-to-carry knife. Its small size and lightweight design make it easy to carry, and its versatility makes it a handy tool to have around. It has a rich history dating back to ancient Japanese warriors, and it’s still made traditionally in Miki, Hyogo Prefecture. While there are challenges with its design, like a loose blade and difficult-to-use chikiri, you can overcome these with care and practice.

Visit our store for high-quality kitchen knives that will change your entire kitchen experience. Read our blog for more information on Japanese knives.